Scintillator Array Inspection System

Pixellated Scintillator Arrays are used in industries such as computerized tomography or in Nuclear technology to convert X Rays or radiation into Visible light in a manner that the resulting light pixels can be absorbed by photo-diodes or photo-detectors and digitized into a meaningful image. The scintillator array is made up of rectangular blocks of 'lumen' arranged in a matrix separated by whitish 'cast' that does not allow the light in one 'lumen pixel' to seep in or influence the intensity of neighboring lumen pixels. Due to the manufacturing process, the scintillators exhibit different kinds of surface defects and inspection systems are very useful to sort for presence, number, classification and severity of these defects. Based on the extent of defect, the scintillator may be thrown away altogether or used for less critical areas of the product employing the scintillator.

I2Seebots' scintillator array inspection system has been deployed and proven in pixellated array production lines with the scintillators being destined for CT scan systems. The scintillators can be inspected by a machine vision camera either on a conveyor (as in the thematic above) or using a manual load pneumatic slide that takes the scintillator into an imaging chamber with visible spectrum or UV illumination being maintained inside a light shroud. Depending on whether the scintillator is moving or not at the time of insopection, a global or rolling shutter machine vision camera is employed and because the defects are often a few tens of microns across, a special lens is used to image them.

Nature of typical defects and impact on product quality:

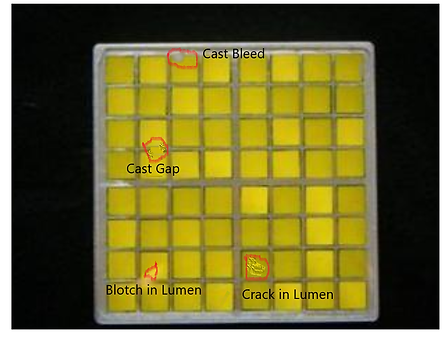

The pixellated array inspection system is capable of detecting, qualifying and quantifying defects such as:

1. Cast bleed-off – The whitish opaque cast 'bleeds off' into the lumen. This reduces the exposed lumen surface in the concerned pixel, thus reducing sensitivity.

2. Gaps in the cast – causes an averaging effect in the intensity perceived by the two pixels on either side of the gap

3. Blotch in the lumen - Seen as a loose smudge on the lumen. Depending on severity, compromises measured intensity on pixel.

4. Crack in the lumen- Distinct from a blotch in respect of the greater sharpness of the defect periphery versus the diffused nature of blotch defect. Impacts measured intensity and robustness of pixel in different ways than the blotch.

Trainable System:

The following measures of quality have been considered in the Automated Optical Inspection system for scintillator arrays:

1) Severity of individual defect in a certain pixel or cast

2) Severity of sum total of defects in a certain pixel giving a measure of quality of the pixel

3) Severity of sum total of defects in all pixels in a scintillator array giving a measure of quality of the scintillator

The system allows for the operator or supervisor to specify algorithms to calculate 3 from 1 or 2 using flexible logical schemes.

Reporting and logging:

-Logging defect data on per scintillator basis to disk

-Logging defect data on per scintillator basis to database or to cloud

-SPC data reporting based on shift, defect type, date etc

-Image logging based on defect thresholds or settings

-Issue reproduction facility to I2SeeBots for maintenance or troubleshoot

Calibration and Debug:

-Calibration of Imaging conditions (see our Calibration page)

-Debug Screen for pneumatic, electrical components to individually operate those components

-RFID or barcode trace-ability if desired

User related :

* Authentication feature for different levels of users

Specifications:

Here is an example of the Scintillator Detector Inspection system implemented by us for a typical user, based on the characteristics of their factory output. If you provide us the data corresponding to your factory output, we can customize for your specifications. Feel free to add any other parameter you feel would be necessary to meet with your specific requirements. There is a mechanism described below to send in your specific Scintillator images if you feel that is necessary.

Commonly Asked Questions related to this Automated Optical Inspection system:

1) Can I2SeeBots confirm feasibility, accuracy, resolution and costs for my specific objects under inspection?

A: Yes. Use the button in the bottom of this page to upload cellphone-snapped images of your Scintillator Array or Similar object under inspection for I2SeeBots to confirm this and provide you with 2-day feedback

2) How does the cost of the Scintillator Array Inspection System compare with building your own solution:

A: I2SeeBots is an expert in Scintillator Array Inspection and have sold/built multiple such systems. The first time we built this solution for a customer, it took roughly 8 man months of experimentation and implementation to build a rugged, error proof system. We are confident, buying the bot will be less expensive and significantly quicker than building and perfecting your own.

3) Will I be able to retain design and source code files for the solution?

A: I2SeeBots will provide mechanical design files and source code for the system.